We supply the most comprehensive robot packaging automation products , including all kinds of packing and palletizing.

The automatic shrink film packing machine is applicable to Food, Beverage, Dairy, Wine, Medicine and Health care, Dairy chemicals and other products of the automatic collective packaging by shrink film.

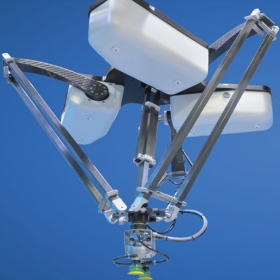

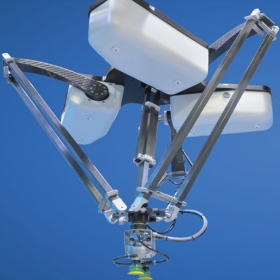

The Multi-function delta robot adopt Genmany Motion Control Systems, and the main parts of robot is German original production, robot protection level: IP65, the robots are widely used in many different packaging process.

The heat shrink film packing machine can be used to Food, Beverage, Dairy Products, Wine Industry, Medicine and health care, Daily chemical industry and other products of plastic packaging, which replace the carton packaging, reduce the cost of package and increase profits.

The automatic case unpacking machine is widely used in Food, Beverage, Medicine, Cosmetic and other industry 's packing line, cartons are formed automatiically, you can chose tape or hot melt glue for sealing.

Machine with autonomous operation to insert in line performing the rinsing the inside of new bottle, filling with still wine in glass bottles, corking with natural cork and aluminium screw cap.

Item NO.:

TRIBLOC “UNIVERSALLead Time:

120daysDESCRIPTION OF THE MACHINE

1. Switch-board in stainless steel Aisi 304 with electrical components assembled in compliance with the norms EN60439-1 CEI17-13/1 EN60204-1

2. Electrical system on the machine with connectors and flame resistant cables.

3. Size parts consisting in inlet screws, star-wheels and conveyors for one bottle format.

4. Star-wheels equipped with devices for the immediate stop of the machine in case of overturned or stuck container.

5. Safety device at the filler outlet to prevent any damage to the valve in case of non-standard bottles.

6. Rinser rotation control shaft clutch with device for the immediate stop in case of defect during the rotation of the machine.

7. Frame of the chassis fully built in tubular rods in electro-welded AISI 304 stainless steel.

8. Adjustable support feet of the chassis in stainless steel AISI 304 with high resistance plastic material bases.

9. Integrated safety guards stainless steel Aisi 304 manufactured in compliance with the “CE” norms in force; upper inspection doors in polimetil metacrilato (PMMA) equipped with safety micro-switches located directly on the hinges to avoid any elusion of the safety devices. The lower part of the machine can be inspected removing the safety panels.

10. Product feed electro-pneumatic valve with adjustable opening and closure (to avoid any water hammer) controlled through level probes.

11. Feed pump connection controlled through level probes.

12. Air treatment device, pressure and container with condense collection filter (Device for the air treatment and pressure equipped with a container with filter for the collection of the condensation).

13. Grease lubrication points gathered on the external vertical rods of the safety guards for an easy access.

14. Machine speed regulation through a potentiometer located on the control board.

15. Mechanical adjustment of the rinsing liquid injection times

16. Regulation of the rinsing liquid pressure through pressure gauge and liquid closure electro-valve.

17. Safety device (no bottle - no spray) to stop the liquid flow in case of lacking container to avoid waste.

18. Completely demountable dripping collection tray for easy cleaning.

19. Easily demountable bottle gripping pads in alimentary graded material (EPDM).

20. Manual device for height adjustment turret.

|

|

|

|

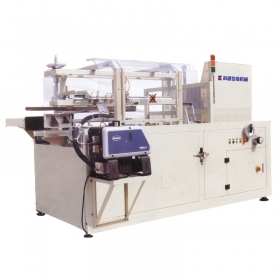

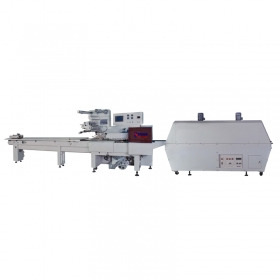

Conventional film packing machine

Conventional film packing machine

The heat shrink film packing machine can be used to Food, Beverage, Dairy Products, Wine Industry, Medicine and health care, Daily chemical industry and other products of plastic packaging, which replace the carton packaging, reduce the cost of package and increase profits.

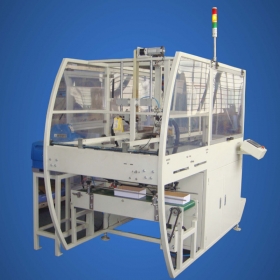

Fully automatic carton packing line

Fully automatic carton packing line

Automatic carton packing line could put packages of various specifications and form into the open carton in shape. Meanwhile, Completed the adhesive or spray sealing and other actions. This process is fully automatic operation.

Automatic box folding machine

Automatic box folding machine

The automatic box folding machine is used to Dairy products, Food, Beverage, Medicine, Cosmetic and another product's tray production automation, which replace manually folding box and maximize the reduction labour intensity of workers.

automatic industrial robot palletizer

automatic industrial robot palletizer

We supply the most comprehensive robot packaging automation products , including all kinds of packing and palletizing.

Delta robot

Delta robot

The Multi-function delta robot adopt Genmany Motion Control Systems, and the main parts of robot is German original production, robot protection level: IP65, the robots are widely used in many different packaging process.

Vertical pillow type shrink packaging machine

Vertical pillow type shrink packaging machine

This Vertical pillow type shrink packaging machine is used for shrink package of food, drinks,medicine and health products, daily, chemical and hardware products, etc. It can protect the products from water, moisture and dust by totally enclosed film packing.

High speed film wrapping machine

High speed film wrapping machine

High Speed Automatic Film Packing Machine can be applied to Automatic Wrapping Film packing production line of Food, Beverage, Dairy Products, Wine Industry, Medicine, Heath Care etc. Featured by high automation degree, simple operation and adjustment. Beside, it also achieve color film positioning packaging.

Automatic carton wrapping machine

Automatic carton wrapping machine

The Auto carton wrapping machine is widely used to Beer, Beverage and other filling products at the end of the production line that allow products to be automatically loaded into the carton. It is also suitable for liquor, wine, pharmaceutical, dairy products, Washing, cosmetics and condiments and other industries.

online service