- 2021-09-10 17:01:17

We supply the most comprehensive robot packaging automation products , including all kinds of packing and palletizing.

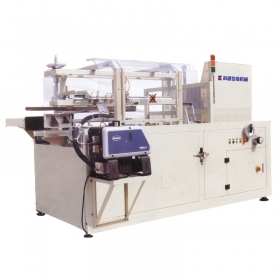

The automatic shrink film packing machine is applicable to Food, Beverage, Dairy, Wine, Medicine and Health care, Dairy chemicals and other products of the automatic collective packaging by shrink film.

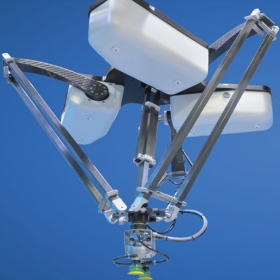

The Multi-function delta robot adopt Genmany Motion Control Systems, and the main parts of robot is German original production, robot protection level: IP65, the robots are widely used in many different packaging process.

The heat shrink film packing machine can be used to Food, Beverage, Dairy Products, Wine Industry, Medicine and health care, Daily chemical industry and other products of plastic packaging, which replace the carton packaging, reduce the cost of package and increase profits.

The automatic case unpacking machine is widely used in Food, Beverage, Medicine, Cosmetic and other industry 's packing line, cartons are formed automatiically, you can chose tape or hot melt glue for sealing.

Product Introduction Infrared Integrated Bridge Cutter is under computerized control, under the touch operating interface, and is equipped with wireless remote control to enable you to operate freely. The main control components are all international famous brand components, the transverse cutter adopts the stepless frequency conversion speed regulation, the beam and the longitudinal splitter...

In the process of use, it is strictly forbidden to extend your hand into the inside of the machine. In any case of machine operation, the protective plate around the blade should not be removed to avoid accidents. In addition, the PCB depaneler is only used as a cutter, and can not be used for other purposes. In the whole process of use, it is necessary to do a good job in electrostatic protection...

Commonly used processing methods now include manual cutting, semi-automatic cutting machine cutting, infrared bridge cutting machine and CNC cutting machine cutting. Although manual cutting is flexible and convenient, the subsequent processing workload is large, the size error is large, the material waste is large, and the working conditions are harsh. , Low production efficiency. T...

online service